Football Crazy

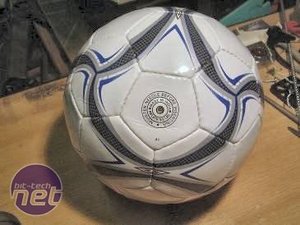

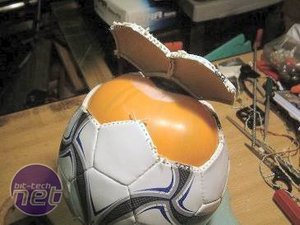

Now comes the time for the fun bit: the football itself. This is a regular size 5 match ball. The first thing to be done was to remove several of the panels to allow access to the inside. The stitching holding the panels together was carefully cut using a sharp knife.

Great care was taken not to burst the balls bladder. The fact that the ball was fully inflated made cutting the stitching easier as the bladder pushed the panels up exposing the stitching.

With the required panels cut, the bladder was burst and removed from the ball.

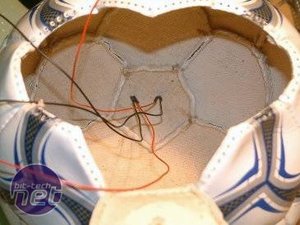

Two 3 mm holes were drilled to accommodate the power and HDD activity LEDs. The LEDs were pre-wired and inserted through the holes. Hot glue was used to retain them in place.

Here you can see the LEDs protruding through the wall of the ball.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.